Explore manufacturing management, its core elements, and job options in Industry 4.0 and explore B.Tech Computer Science scope with NAMTECH. Learn more.

What is Manufacturing Management, Its Aspects and Career Opportunities in Industry 4.0?

Techno-managers for smart manufacturing require a combination of technical and management skills. Therefore, it is logical to look for a holistic smart manufacturing program that provides an alternate to MBA and an alternate to M.Tech and kick start your prospective career in Industry 4.0 with core skills in both domains. It is the need of the hour as the education system and industry aspirations are evolving with trends like interdisciplinary education and cross-functional job roles.

People looking to pursue a smart manufacturing program from new-age institutes like NAMTECH get hands-on learning experience in manufacturing management concepts. You can explore curated courses like iPMP in Smart Manufacturing and iPTP-A (Automation) with exceptional learning outcomes.

Graduates and diploma holders learn various core concepts of smart manufacturing through an optimised blend of classroom and practical education. Manufacturing management is one of the core concepts you study in these smart manufacturing programs. For today’s passage, we chose to explore this vital aspect and diverse career avenues in the same for your reference.

What is Manufacturing Management?

Manufacturing management in Industry 4.0 is the process of planning, scheduling, and executing production in a factory setting. Manufacturing managers supervise production facilities and coordinate between workers and senior management. They also deal with vendors, suppliers, partners, and clients. They run an entire plant with a responsibility to maintain quality and performance.

Responsibilities of a Manufacturing Manager in Industry 4.0

- Manufacturing managers supervise the regular operations of manufacturing facilities. This includes coordinating, planning, and directing all the activities involved in the production process.

- Managing an entire plant or a specific part of the facility differs from organisation to organisation, job title to job, and scope of work.

- Generally, manufacturing management includes setting up the machines and equipment and creating a safe environment for manufacturing.

- Workflow management and ensuring efficiency during the production process

- Supervising the quality aspect of manufactured goods and materials. Smart manufacturing programs train professionals to learn technical and life skills to lead future factories. Programs like iPMP at NAMTECH are a perfect alternate to M.Tech and an alternate to MBA for your prosperous career in the evolving manufacturing landscape of India.

- Ensure production is on schedule, set goals for production, and coordinate to reach the goals in the plan.

- Writing production reports, ensuring quality as per company guidelines and industry standards

- Analyzing manufacturing data and optimizing the workflow for overall efficiency, including productive flow of resources and efficient equipment layout

- Close vigil on hiccups in production and look for sustainable and innovative solutions to solve any possible issues.

- Ensuring workers meet their KPIs and machines meet desired performance with safety intact and minimum human errors.

- India requires advanced manufacturing education to train smart manufacturing professionals and run future factories with skills in strategy, planning, and I4.0 technologies.

- A manufacturing manager’s job also includes hiring, training, and assessing the performance of team members, workers, and junior staff.

- Leading organisations offer Industry 4.0 training to workers and employees. Manufacturing managers with smart manufacturing programs are equipped with the required skills, which provides an edge over fellow managers and employees. Explore and apply for NAMTECH admissions to get ahead of the competition in future factories.

- Manufacturing managers also engage in cross-departmental communications, such as with HR for hiring, the finance department for budgeting, and the logistics department for delivery and supply of goods.

Manufacturing management is a broader term and covers several job roles that can be separate designations in diverse manufacturing organisations. In the following section, we will explore career avenues you can explore with a degree in manufacturing management or a smart manufacturing degree from new-age institutes like NAMTECH.

Career Opportunities in Manufacturing Management in Industry 4.0

- Quality Control Manager

- Logistics Manager

- Operations Manager

- Purchasing Manager/Associate

- Line Supervisor

- Production Planner

- Facilities Supervisor

- Inspection Supervisor

- Safety Supervisor

- Inventory Manager

- Maintenance Supervisor

- Shipping and Receiving Manager

- Manufacturing Supervisor

Learn manufacturing management with the iPMP Program at NAMTECH. Here are key aspects of the program and why it’s the best option for your desired career flight in the future of smart manufacturing.

The iPMP Program: Grooming Techno-Managers for the Sustainable and Efficient Manufacturing Management

- Course Name: International Professional Masters Program

- Duration: Residential 12 months program in 4 trimesters, each of 12 weeks

- Eligibility: BE/BTech (2019 or later) with minimum 65% marks in 10th, 12th, and Graduation

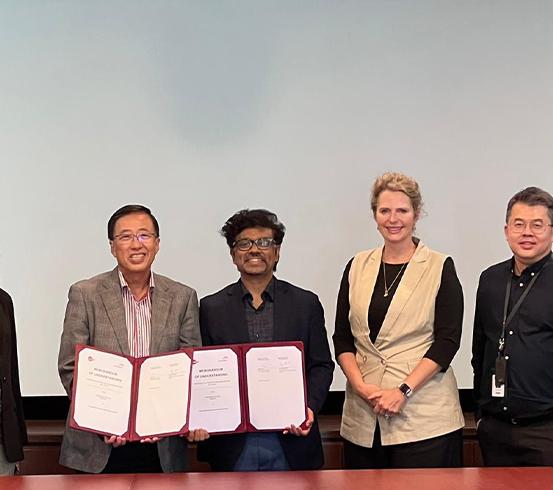

- Campus: NAMTECH India (Campus: IIT Gandhinagar) and TUM Asia, TUM Germany

- Commencement Date: August 2024

- Early Application Deadline: 30th June 2024

Aspects of the iPMP Program

With the iPMP program of NAMTECH, students learn the following subjects of smart manufacturing and develop skills to run future factories. The iPMP curriculum has four interrelated threads: Technology, Engineering, Design, and Management (TEDM). The smart manufacturing program is supported by industry-simulated labs with software and state-of-the-art sophisticated equipment.

Trimester 1: Essentials of Advanced Manufacturing Education, Hydraulic Technology, PLC Programming, Industrial Internet of Things, Manufacturing Management, Pneumatic Technology, Servo/Stepper Systems & Smart Sensors, Industrial Robots, Data Visualisation with NOD RED Programming, Communication Skills and Team-Work Development

Trimester 2: Data Analytics, PLC Programming with HMI & Ethernet Communication, Software Coding (Python, NL and Lab View), Digital Twin in Manufacturing, Finance Management, Collaborative Robots, AI & ML in Manufacturing, Project Management, Advanced Machining (Additive and Subtractive using metals) and Product Design and Rapid Prototyping

Trimester 3: Digital Twin in Manufacturing (Tecnomatix Simulation), Cyber-Physical Systems (Smart Factory), Sustainability for Smart Manufacturing, Health, Safety & Environment, Digitalising Operation with MES, Cyber Security, Reliability & Quality for Engineers, and Operational Excellence

Trimester 4: Industry Internship and Capstone Project

Explore the iPMP program and develop an in-depth understanding of manufacturing management in Industry 4.0 to expand B.Tech Computer Science scope to leverage job opportunities in the evolving manufacturing sector in India