The web is buzzing with searches about industry 4.0, smart manufacturing, and related topics. A study says public search has spiked around 140 times since its first mention by German Chancellor Angela Merkel in 2011 during the Hannover Fair and Acatech, Germany’s Academy of Engineering.

More than fifty thousand research papers were published on topics related to Industry 4.0 and smart manufacturing in 2021 alone. A Deloitte study states, “Approximately 83% of manufacturers believe that smart factory solutions will redefine the methods products are produced in five years. Prominent future job roles will be Digital Twin Engineer, Predictive Supply Network Analyst, Drone Data Coordinator, Digital Offering Manager, and Smart Factory Manager.”

It’s time to rethink how you want to skill yourself to engineer the future of manufacturing. Sorry to break it to you, but a conventional engineering degree won’t be sufficient to meet the needs of future factories. You require a professional master’s program in smart manufacturing to know all about it to become a sustainable and future-ready engineer.

Let us examine what smart manufacturing is and all about it for your reference while making academic and career decisions.

What is Smart Manufacturing?

The National Science Foundation of the USA coined “smart manufacturing” in 2006 at a workshop on Cyberinfrastructure. Initially, it was called “smart process manufacturing” and emerged with new technologies like artificial intelligence, 3D printing and more.

Smart manufacturing is an advanced production process that is automated, interconnected, and data-rich. It is a collaboration of people, machines, and big data into an integrated and digitally connected system. This system aggregates and analyses data for understanding, predictions and gaining insights. Students with a professional master’s program in smart manufacturing can also recommend automated processes and efficient workflows.

Smart manufacturing employs technology-based high-end solutions and processes. These solutions are sustainable, scalable, secure, open & interoperable, proactive, semi-autonomous, and resilient.

Smart manufacturing combines new-age technologies and processes, including AI, cybersecurity, robotics, blockchain, and the industrial Internet of Things. These technologies of Industry 4.0 optimise the manufacturing ecosystem and improve its performance overall.

Components of Smart Manufacturing

Components of smart manufacturing are revolutionising manufacturing procedures, making it safe and efficient. Some prominent components of smart manufacturing are;

- Internet of Things

- Cloud Computing

- Digital Twins

- Additive Manufacturing

- Robotics

- Big Data

- Cyber-Physical System

Advantages of Smart Manufacturing Program in 2024 and Beyond

- Increased adaptation of AI in manufacturing will encourage further automation and improve production processes with data-based decision-making.

- Cloud computing provides an efficient and safe platform for storing and processing data.

- Manufacturers can conveniently aggregate and analyse data from diverse sources and utilise it for different purposes to improve the manufacturing process.

- Greater adoption of cloud computing is evident all across industries. New-age manufacturers can analyse data remotely. It does not require hardware or software.

- Organisations implement II0T (Industrial Internet of Things) software into their smart manufacturing set-up to aggregate machine data and store it in cloud storage.

- Share cloud storage is another crucial advantage which organisations are using these days. Stored data can be utilised later for processing.

- The proliferation of connected devices and sensors to collect data from products, environment and machines. This data will be used to boost quality, safety, and efficiency.

- 3D printing and additive manufacturing technologies are highly advanced industry 4.0 technologies. Manufacturers use these to design and create new products and optimise manufacturing processes.

- Experts believe there will be technologically transformed smart manufacturing plants in 2024 and beyond, running entirely on smart technologies mentioned above.

- Future factories will be efficient, productive, sustainable, and tech-dependent.

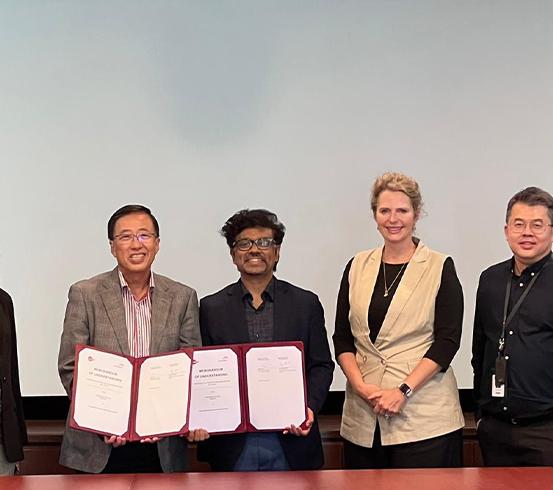

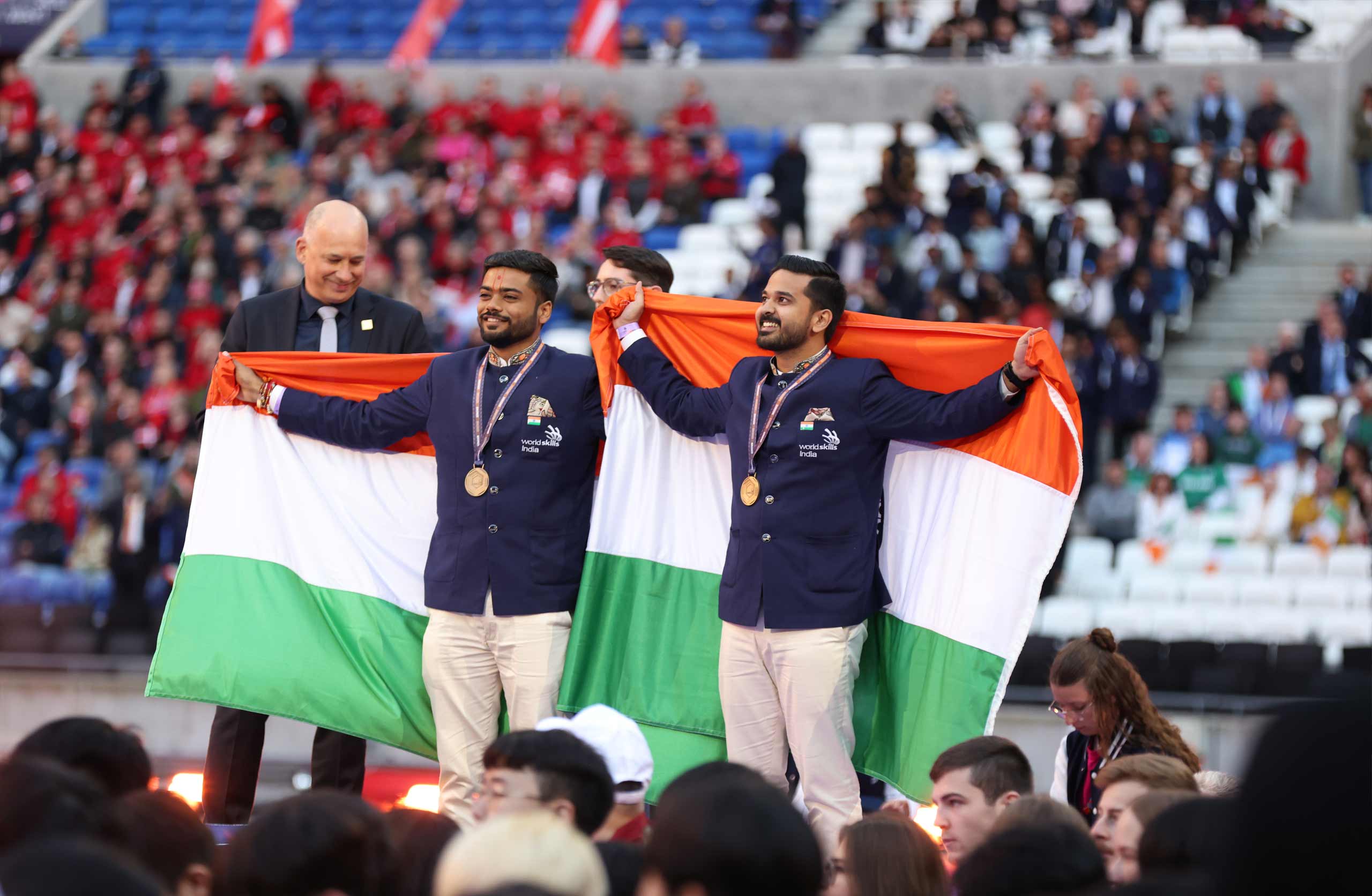

- Smart manufacturing programs at new-era universities like NAMTECH build on BTech and Engineering degrees and prepare future-ready tech professionals.

- Technologies of Industry 4.0 help to minimise waste, reduce production times, and boost productivity. An efficient manufacturing process saves the cost of production and increases profit.

- Data-based manufacturing processes, decision-making and minimum errors ensure improved quality.

When the quality of the final products improves, it reduces recalls, saves on wastage, enhances trust in customers and more. - Smart manufacturing technologies help organisations quickly adapt to changes or supply quickly. Engineers having a master’s program with global immersion at NAMTECH become ready for future factories.

- Optimising the manufacturing process minimises costs and boosts profitability. Smart manufacturing ensures sustainable practices and encourages green and eco-friendly methods.

The impact of smart manufacturing on improving global warming and pollution is significant. The manufacturing industry consumes around 54% of the energy consumption globally and is responsible for approximately 20% of global carbon emissions. It is a highly resource-intensive industry with an adverse impact on the environment.

The traditional manufacturing industry massively generates water and industrial waste and greenhouse gas emissions. The solution could be the global adaptation of smart manufacturing technologies and transforming them into future green manufacturing factories.

Notable Trends in Smart Manufacturing 2024 and Beyond

- More opportunities for off-site, remote and hybrid operational work

- Further exploration and adoption of AI and VR

- Machine condition monitoring and maintenance with sensors

- Changing personnel functions

- Rise of cobots or collaborative robots

- Extensive adoption of RPA and related technologies

- More predictive approach for maintenance, operations, and more

- Change of manufacturing personnel’s job roles and skill sets

Conclusion

The world needs smart manufacturing professionals to run future factories. Apply for a smart manufacturing program, get ready with industry-ready skills, and commence a glorious career in Industry 4.0. Let’s conclude with how big smart manufacturing is turning out to be in the near future.

According to Mordor Intelligence, the smart manufacturing market was estimated at $141.39 billion in 2024 and is projected to reach $279.23 billion by 2029. Transparency Market Research (TMR) estimates the global smart manufacturing market will reach $548.14 billion by 2024.